National University of Kaohsiung / Prof. Wen-Fu Ho

Pain Points Solved

Currently, the surfaces of titanium alloy implants commonly used in clinical practice are biologically inert and have insufficient bonding strength with bone tissue, often requiring additional surface modification or coatings to improve osseointegration. On the other hand, natural bone possesses piezoelectric properties, which can promote cell differentiation and proliferation through electrical signals during the bone remodeling process, accelerating bone healing. However, existing piezoelectric materials such as Lead Zirconate Titanate (PZT) contain lead and cannot be applied in the biomedical field.

This patent proposes a novel process that directly forms a piezoelectric nanostructure on the surface of titanium-containing alloy implants and can further cover it with calcium titanate crystals, creating an implant that possesses both bioactivity and piezoelectricity.

Technology Introduction

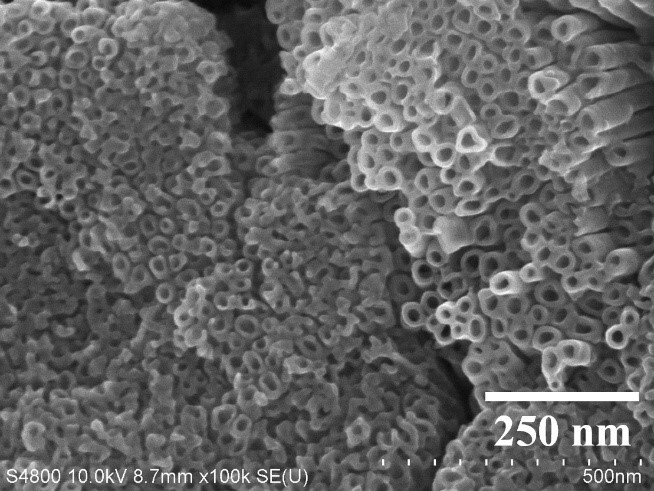

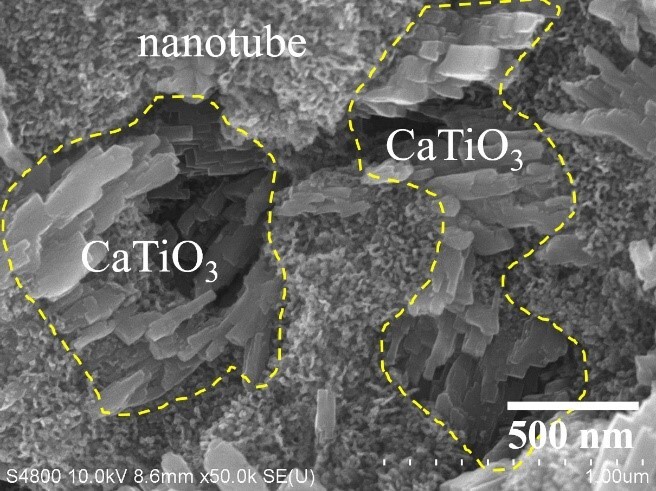

This technology uses anodic oxidation combined with microwave heat treatment as the core process to directly generate piezoelectric titanium dioxide nanotube structures on the surface of titanium-containing alloys. Through further hydrothermal treatment, a coating of calcium titanate crystal particles can be formed on the surface of the nanotubes, endowing the material with both bioactivity and biopiezoelectricity. Compared to traditional titanium alloy implants that are merely biocompatible, the surface structure produced by this technology can effectively promote the attachment, proliferation, and differentiation of bone cells, accelerating the osseointegration and healing process.

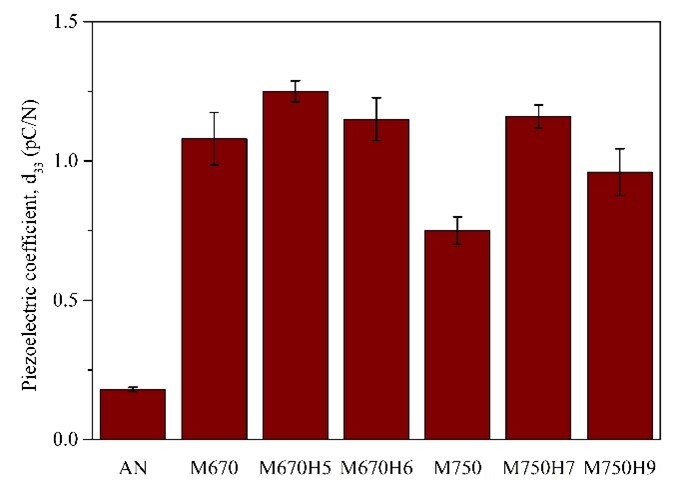

Simultaneously, compared to high-piezoelectric materials (like PZT) that require polarization and contain lead, this technology not only avoids the toxicity issue of lead elements but also exhibits stable piezoelectric performance without polarization conditions. Tests show that the piezoelectric constant of this material reaches 0.9–1.2 pC/N, which is higher than that of natural bone (approx. 0.7 pC/N), demonstrating significant advantages in bone healing promotion, smart implants, and biosensing applications. Furthermore, this process features simple operation, low cost, and mass production capability, holding high industrial application potential, especially for the development of next-generation smart biomedical implant materials.

▲Caption: Titanium dioxide nanotube structure with piezoelectric properties.

▲Caption: Nanotube and calcium titanate structure possessing both bioactivity and biopiezoelectricity.

▲Caption: The alloy surface prepared by this technology process possesses a high piezoelectric constant.

Application Examples

In terms of application, this technology is particularly suitable for the medical device industry, including orthopedic implants such as artificial joints, bone screws, bone plates, and spinal fusion cages, as well as dental implants such as implant screws and alveolar repair materials. Since the material possesses both piezoelectric effects and bioactivity, it can also be applied to smart medical devices in the future as a bone healing monitoring platform with piezoelectric sensing functions.

Related Links

None

Patent Name and Number

ROC Patent, Invention No. I881623, 2025/04/21 - 2043/12/21

Industry-Academia / Tech Transfer Partner

None

Honors and Awards

None

Technical Contact

Vivian Lee, Administrative Assistant

National University of Kaohsiung

Tel: +886 7-5916639

Email: vivianlee@nuk.edu.tw