National University of Kaohsiung / Prof. Yi-Chang Chung

Pain Points Solved

This technology uses eggshells as raw materials to develop an energy-saving and highly efficient CaO-modified photocatalyst. It successfully shortens the process, which originally required high-temperature and long-duration calcination, to within 30 minutes, significantly reducing energy consumption and carbon emissions. Through doping with different elements, the photocatalyst possesses a tunable bandgap, enabling it to absorb visible light and efficiently degrade dyes and ammonia nitrogen in industrial and household wastewater, effectively improving water quality. Simultaneously, the CaO-based catalyst can be used for the degradation of plastics and microplastics; under sunlight or microwave irradiation, it can recover monomers or convert them into high-value carbon materials, enhancing the value of resource reuse.

Technology Introduction

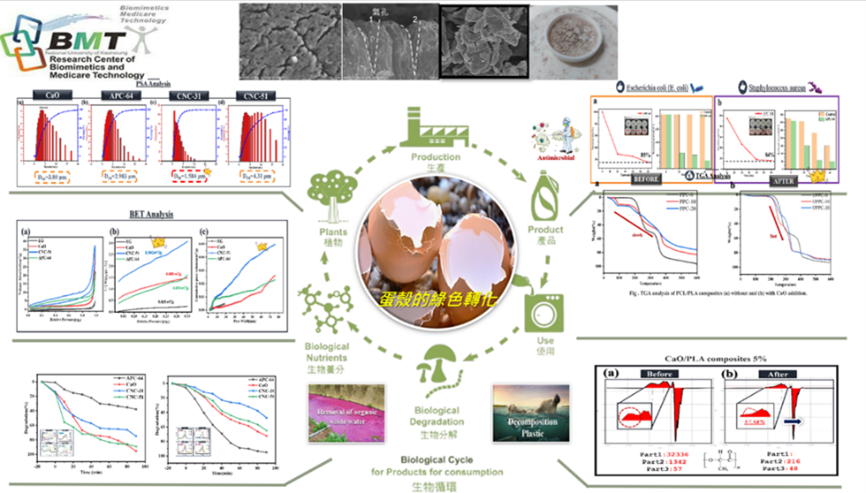

This "Eggshell-Derived CaO Modified Photocatalyst Technology" takes biomimetics as its core concept, breaking through the limitations of traditional photocatalysts made from dense shell materials like oysters and seashells. The surface of an eggshell has approximately 7,500 to 12,000 pores. After heating to remove CO₂, its natural porous structure can directly form CaO powder with an extremely large specific surface area without complex grinding, providing a higher reaction rate. This technology employs a high-efficiency energy-saving process that completes the conversion of CaCO₃ to CaO in just 30 minutes, significantly reducing energy consumption and time. At the same time, it utilizes instantaneous high temperatures to create a co-firing effect with doped materials, forming abundant surface defects and promoting electron-hole separation. This allows the photocatalyst to absorb broad-spectrum energy from visible light to UV light, thereby efficiently degrading dyes and ammonia nitrogen in wastewater. Furthermore, this technology has developed an application using CaO-based catalysts for plastic pyrolysis for the first time. It can decompose plastics such as PET, PLA, PCL, and PS under light or microwave heating. Through radical reactions, it depolymerizes the polymer main chain to recover monomers, oligomers, or carbon quantum dots, achieving high-value plastic reuse. This technology integrates multiple functions such as waste eggshell regeneration, energy-saving processes, wastewater purification, plastic degradation, and antibacterial properties, demonstrating the sustainable environmental value of "using waste to treat waste."

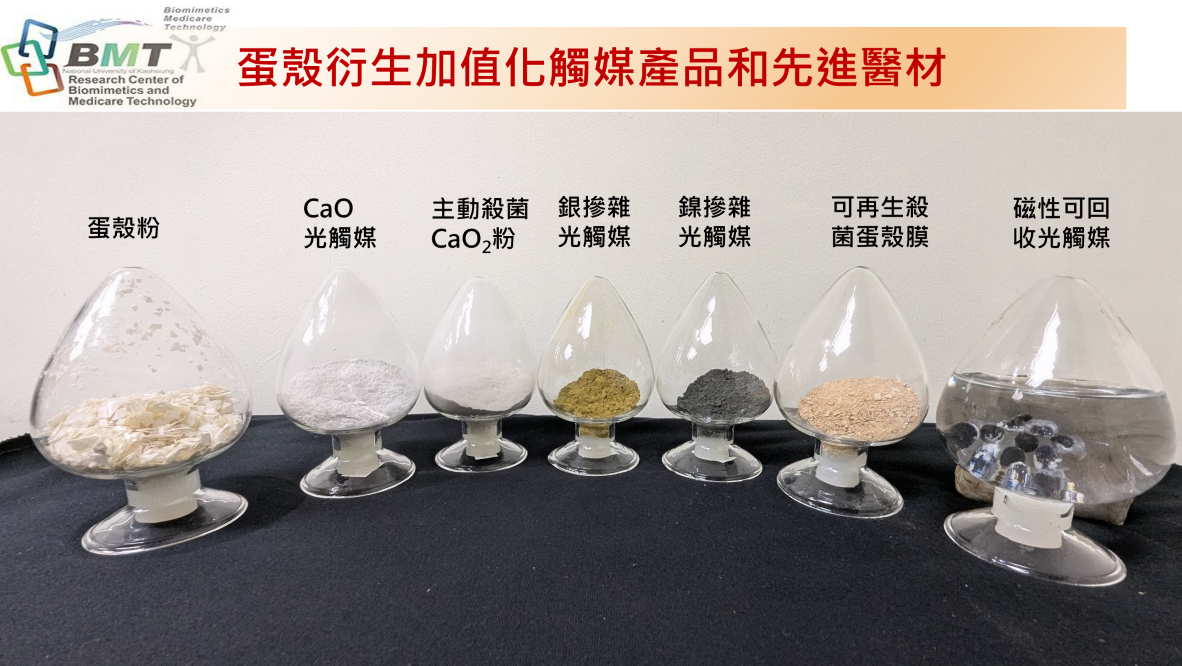

Figure 1. Eggshell-derived value-added catalyst products and advanced medical materials.

Figure 2. Characteristics of various substrates.

Figure 3. Applications of eggshells.

Application Examples

1. Eggshell Processing Technology:

Utilizes high-efficiency microwaves to convert eggshells into CaO photocatalysts within a short time. Instant heating co-firing forms defects on the material surface, promoting electron-hole separation and generating free radicals to enhance catalytic efficiency. It can be applied to egg product processing, catering, and food manufacturing industries to establish a waste recycling system.

2. Photocatalyst Wastewater Treatment Application:

The developed novel CaO photocatalyst can utilize sunlight to decompose organic pollutants such as dyes and ammonia nitrogen in water, achieving efficient water purification and carbon fixation recycling. It can be applied to wastewater treatment fields in chemical engineering, dyeing and finishing, livestock, and industrial zones.

3. Plastic Decomposition Application:

Using CaO-based catalysts combined with light or microwave reaction, it can decompose plastics like PET, PLA, PCL, and PS, recovering monomers, oligomers, or converting them into high-value carbon materials. This provides a new solution for plastic recycling and microplastic treatment. It can be applied to chemical, plastic, and recycling industries.

4. Light-Induced Sterilization Application:

CaO photocatalysts can absorb UV to visible light, producing free radicals for active sterilization, with highly effective inhibitory effects on E. coli and Staphylococcus aureus. Applied in indoor/outdoor environments, farms, and public spaces, the product becomes stable calcium carbonate with no secondary pollution, offering environmental and sustainable benefits.

Related Links

None

Patent Name and Number

114110143 (Patent under review, details not disclosed)

Industry-Academia / Tech Transfer Partner

None

Honors and Awards

Future Tech Award

Technical Contact

Vivian Lee, Administrative Assistant

National University of Kaohsiung

Tel: +886 7-5916639

Email: vivianlee@nuk.edu.tw