Search

﹤AI、Smart Manufacturing﹥Deep Learning Image Recognition Applied to Robotic Arm Guidance and AOI Inspection Technology

National University of Kaohsiung / Prof. Cheng-Hong Wu

Pain Points Solved

This technology offers a solution to the problems of rigid positioning, difficult adjustments, low quality control efficiency, and lack of flexibility in traditional automated production lines. By installing a camera on a robotic arm and combining it with Deep Learning Image Recognition (CNN) and an object database, the robotic arm is endowed with visual recognition and autonomous operation capabilities. It can track and grip moving objects in real-time, enhancing production line flexibility and precision. Simultaneously, by introducing Automatic Optical Inspection (AOI) and a learnable classification system, it can automatically identify defects and trace the source of anomalies, improving quality control efficiency and product yield, thereby realizing a smart manufacturing process for high-mix low-volume production.

Technology Introduction

This technology combines Industry 4.0 and Artificial Intelligence image recognition technology to develop a smart robotic arm system with visual positioning and autonomous operation capabilities. By installing a camera on the robotic arm and utilizing Deep Learning Convolutional Neural Networks (CNN) and an object feature database, the robotic arm can "see and understand" the location and type of products or tools, autonomously completing tasks such as gripping, assembly, and sorting. The system possesses high flexibility in positioning; it can correct operation paths in real-time even if the object's position changes, solving the issues of rigid positioning and difficult adjustments in traditional automated lines. Furthermore, paired with an Automatic Optical Inspection (AOI) module and an updateable learning classification engine, it can rapidly identify product defects and trace anomaly sources, enhancing quality control efficiency and production yield. The overall technology can be applied to smart manufacturing, high-mix low-volume production, and academic/research automation fields, demonstrating highly flexible and intelligent manufacturing capabilities.

▲Caption: Robotic arm and image sensor.

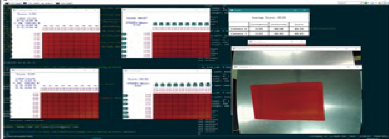

▲Caption: Quality Inspection - Biomimetic Tape Smart Inspection Software Module.

▲Caption: Deep Learning Image Recognition Applied to Robotic Arm Guidance Technology - Biomimetic Tape Smart Manufacturing Application Module.

▲Caption: Quality Inspection Machine Hardware Module

Application Examples

This research technology is suitable for introduction into various academic/research institutions, manufacturers, chemical, and medical industries. It targets manual small-volume manufacturing and highly repetitive experiments, reducing human factor interference, thereby achieving the effects of saving labor and reducing errors.

Related Links

https://www.youtube.com/watch?v=Yc2koWXmFo8

Patent Name and Number

None

Industry-Academia / Tech Transfer Partner

None

Honors and Awards

None

Technical Contact

Vivian Lee, Administrative Assistant

National University of Kaohsiung

Tel: +886 7-5916639

Email: vivianlee@nuk.edu.tw