﹤Biotech & Biomed Innovation﹥High-Efficiency Cell and Viral Mass Production Platform

National Pingtung University of Science and Technology / Prof. Guan-Ming Ke

Pain Points Solved

Vaccine development is about more than just identifying viruses or designing antigens. One of the most critical yet frequently overlooked steps is finding reliable cells capable of growing large quantities of viruses safely and consistently. Without suitable cells, production timelines can stretch from weeks to months, significantly driving up costs and restricting supply.

A research team at National Pingtung University of Science and Technology (NPUST) has developed a non-genetically modified (non-GM) cell engineering platform to address these challenges in animal vaccine production. In this context, "non-GM" means the cells' DNA is not deliberately altered in a laboratory setting.

While many current manufacturing systems rely on genetically modified cells to boost productivity, these methods often face lengthier regulatory reviews and greater complexity when scaling up. The Taiwanese team took a different approach: harnessing the cells' natural capabilities rather than modifying their genes.

"Instead of redesigning the factory, we focus on 'auditioning' the best workers and building the ideal workplace," says Professor Guan-Ming Ke of the Graduate Institute of Animal Vaccine Technology at NPUST. "We screen thousands of individual cells to identify top performers and place them in strictly controlled conditions—much like providing skilled employees with the right tools, training, and environment to perform consistently over the long term."

Technology Introduction

Through this approach, researchers can transform ordinary cells into high-efficiency virus "factories," capable of producing millions to tens of millions of viral particles per production cycle—a yield level typically required for industrial-scale vaccine manufacturing. The platform has already been demonstrated across various diseases affecting pigs, poultry, and fish, as well as the Dengue virus, proving its versatility and adaptability beyond a single pathogen or animal species.

This method also offers clear ethical benefits. By propagating viruses within stable, well-characterized cell lines, the platform reduces the reliance on live animals for virus replication—a practice that still persists in certain vaccine development workflows. In practice, this significantly reduces the use of experimental animals while improving consistency and repeatability between production batches.

Cost and scalability were also core considerations in the platform's design. Many of these cells can be cultured without animal serum, a component that typically accounts for 30–50% of total cell culture costs. Furthermore, these cells can be expanded in large, free-floating suspension batches suitable for bioreactors with capacities ranging from hundreds to thousands of liters. This makes the transition from laboratory scale to manufacturing facilities easier and the overall production costs more affordable.

Figure1. Serum-free suspension cell culture system designed to enhance viral yield and reduce costs.

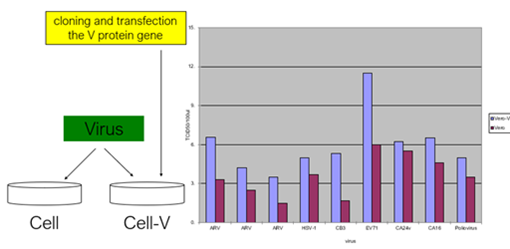

Figure2. Modified Vero cells expressing the V protein exhibit enhanced viral susceptibility.

Application Examples

In practical application, the platform integrates precise selection of high-performing cell and virus strains, methods to enhance cellular resilience against production stress, and enclosed, monitored culture systems that maintain stable conditions as production scales up.

According to the research team, the platform is built upon over 10 years of accumulated expertise and dozens of newly established cell lines from multiple animal species. It is designed to complement existing vaccine technologies by reducing costs, risks, and development time during the most critical stages of vaccine production.

Related Links

None

Patent Name and Number

None

Industry-Academia / Tech Transfer Partner

Industry-Academia Cooperation: Taiwan、Indonesia、France、Korea、Japan

Honors and Awards

None

Technical Contact

Joan Li, Project Manager

National Pingtung University of Science and Technology

Tel: +886 8-7703202 ext. 6571

Email: joanli@mail.npust.edu.tw